Company reaffirms its aim of improving aircraft performance, reliability

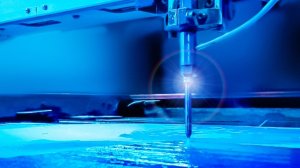

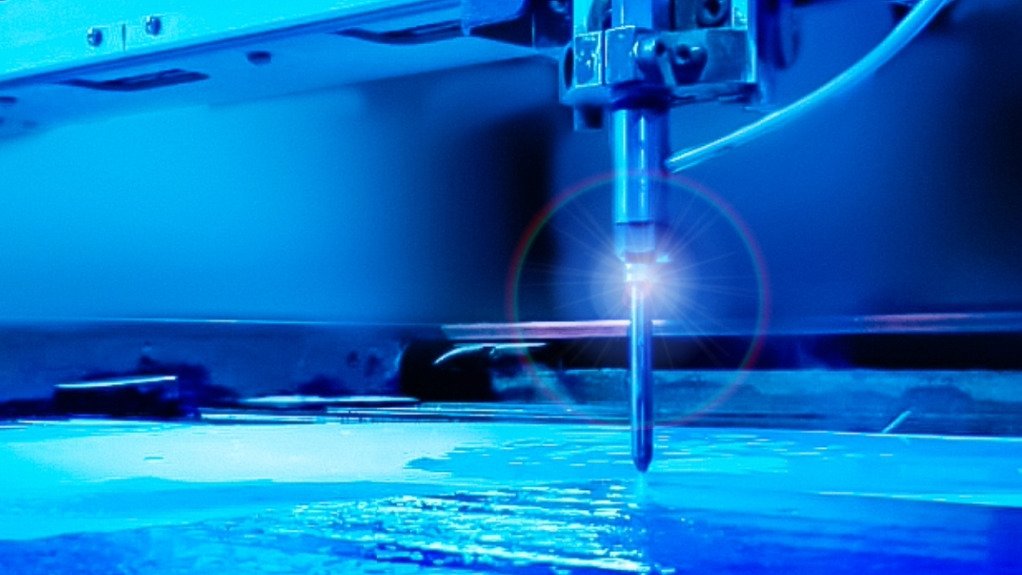

COST EFFECTIVENESS Waterjet cutting provides a cost-effective alternative for high-precision cutting, especially for expensive materials or complex designs, by minimising material waste and reducing labor costs associated with secondary operations

An increased focus on developing innovative waterjet cutting technologies for the structural integrity of critical flight components is crucial in offering a safe, precise and versatile solution for producing high-quality, high-tolerance parts for aircraft, states waterjet cutting service MAXJET MD Preeshan Naidoo.

With over 20 years’ experience in the promotion and supply of waterjet cutting services, Naidoo notes that MAXJET has over the decades been able to supply several parts in various materials for ‘high profile’ blue chip aerospace companies. These range from domestic to commercial or military aircraft.

The ‘high’ pressure waterjet cutting systems that use abrasives for cutting were intentionally developed for aerospace industries as the process uses a cold cutting method, which allows for the machining and cutting of parts without changing the inherent structural integrity of the materials, further enhancing their lifespan.

Aerospace adopts extremely stringent quality and traceability standards for manufactured parts. Strict audits are conducted on suppliers for approvals.

“The general materials processed by MAXJET for the industry are titanium, aircraft-grade aluminium, carbon fibre, honey-comb aluminium and insulation materials. Our general tolerances are between 0.15 mm and 0.3 mm depend on material type and thickness. We’re able to process materials from 0.25 mm to 300 mm thick,” says Naidoo.

He adds that MAXJET’s quality control procedures have been adapted for the aerospace industry and a huge benefit for other clients is that MAXJET has made the current quality control plan (QCP) the company standard.

MAXJET’s average turnaround time is three to five days from the order date and can be even quicker if an order is placed on a “breakdown basis”. The company endeavours to provide a prompt, quality and efficient service.

“While South Africa’s economy may be affected by the imposed tariffs mainly affecting the automotive and agricultural industries, it may be fruitful for leaders to reflect on past successes that propelled the South African economy. South Africa manufactured full aircraft since the late 1920s, more than a century ago, and with this heritage we should have been at the forefront of aerospace manufacturing,” Naidoo highlights.

The Atlas Aircraft Corporation – which formed in the 1960s and led domestic production for military and avionics systems for the South African Air Force – eventually became the Denel group, which had productive component supply partnerships with international original-equipment manufacturers such as Airbus and Boeing.

Most of these components were largely used for the Airbus A400M project.

“I’m proud to have personally been part of the supply and manufacture of components to Denel-SAAB.” At the time, Denel-SAAB was manufacturing and assembling leading Gripen fighter jets.

He adds that the local aerospace industry, in the earlier part of this millennium, was worth “more than about R5-billion a year, excluding the private sector”.

Naidoo says that, two decades later, the aerospace industry should be much better off than the state in which it currently finds itself; however, he also draws inspiration from reflecting on the positive history of the South African aerospace industry. He hopes that a shared perspective of this history will help to enhance and stimulate growth within the economy and add to job creation while attracting foreign investment.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation